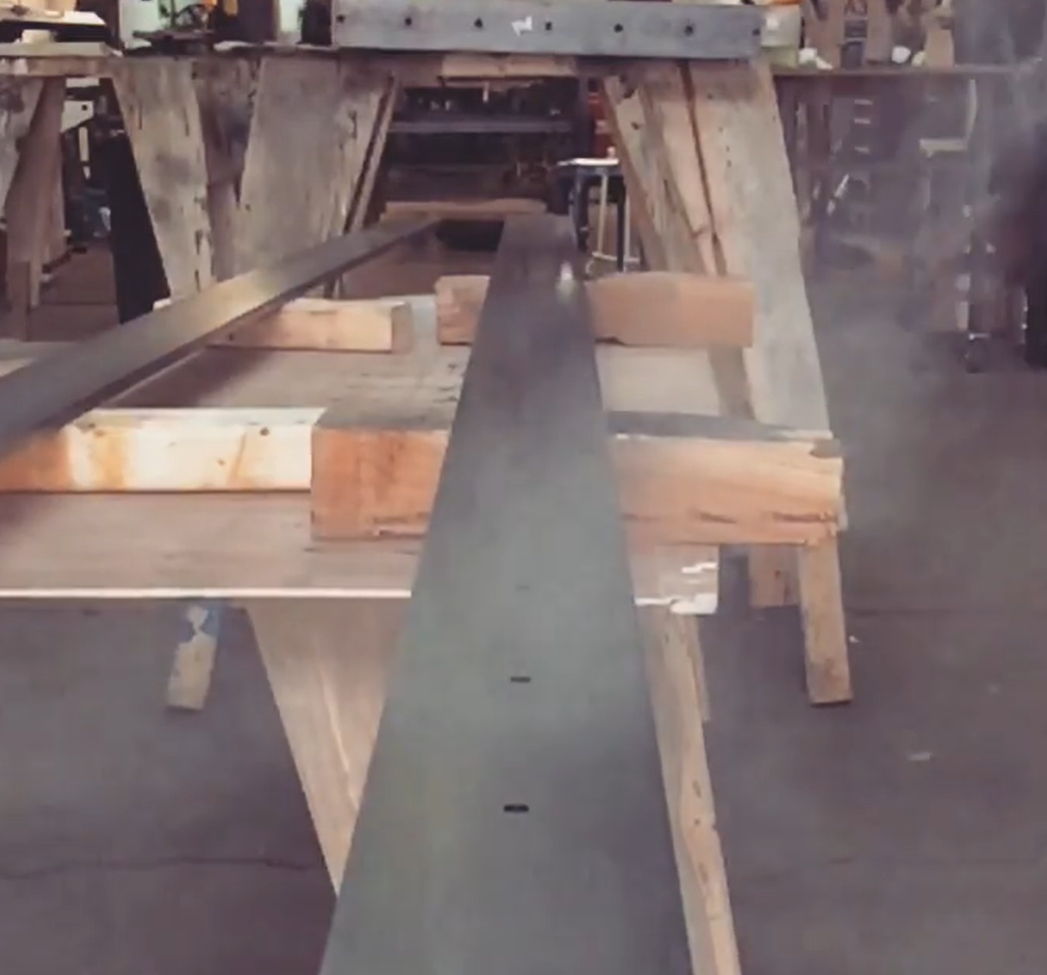

FABRICATION IS THE CORE OF OUR BUSINESS

Freehand Metalworks ensures that every technique we use to create your project is done with intent, care and precision. Each work at Freehand Metalwork is hand crafted using skills mastered over thousands of hours.

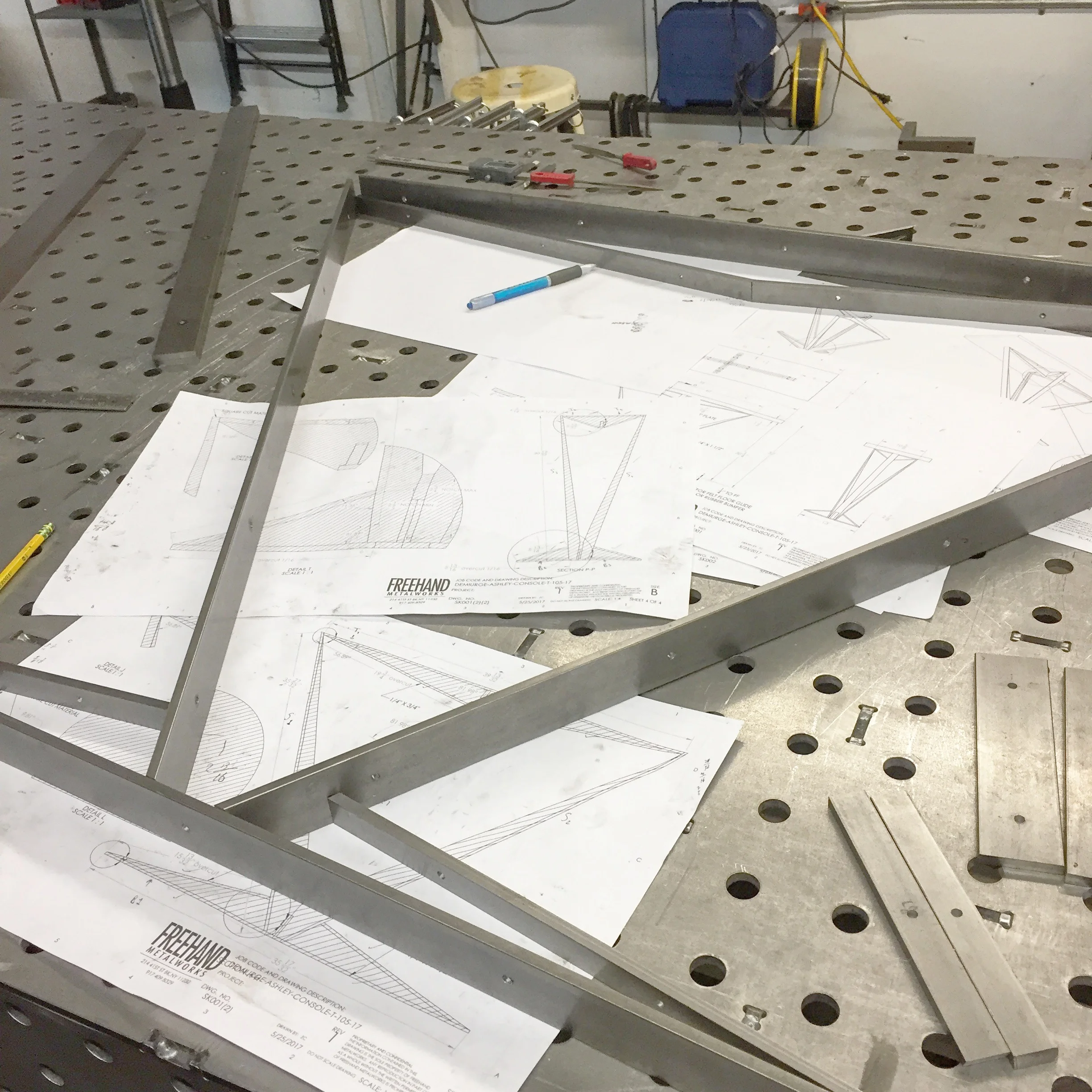

Freehand Metalworks takes a manufacturers approach but has the diversity of a job shop. Each product is made with intent. We produce products that have the precision of an OEM(Original Equipment Manufacturer) and the character of a blacksmith. We approach every project thinking about technique first. We use manual tools when needed and CNC when appropriate. We know when to be precise and know when to work quickly to complete the work one time, within budget and to the quality desired.

Our in house equipment list is quite extensive and we reserve each machine for your custom project. We do not take material cut orders backing up our CNC plasma cutter, or offer our sand blasting services, or machine customers existing components on our CNC mill. Our shop is dedicated to your custom project from start to finish. Upon material receival we perform a quality control procedure to ensure each piece is free of defect. We then begin to process the material according to the drawings. All components are cleaned, deburred and sanded along the way. Once the material is cut and prepped it moves to our assembly and fixturing area. There the product starts to take form being welded or prepped and fastened together. In-house components are combined with purchased components and the piece takes final firm however in a raw state. The project again goes through a quality control procedure and your project is either finished as a whole or broken down into components for pieces to be finished individually. Hand applied artisanal finishes are quite labor intensive and when chosen products may spend a lot of time being finished and refinished if required.