DRAWING AND DESIGN SERVICES

We work directly with our clients to understand their aesthetic perspective and offer direction to come up with an elevated product with hits all of the goals.

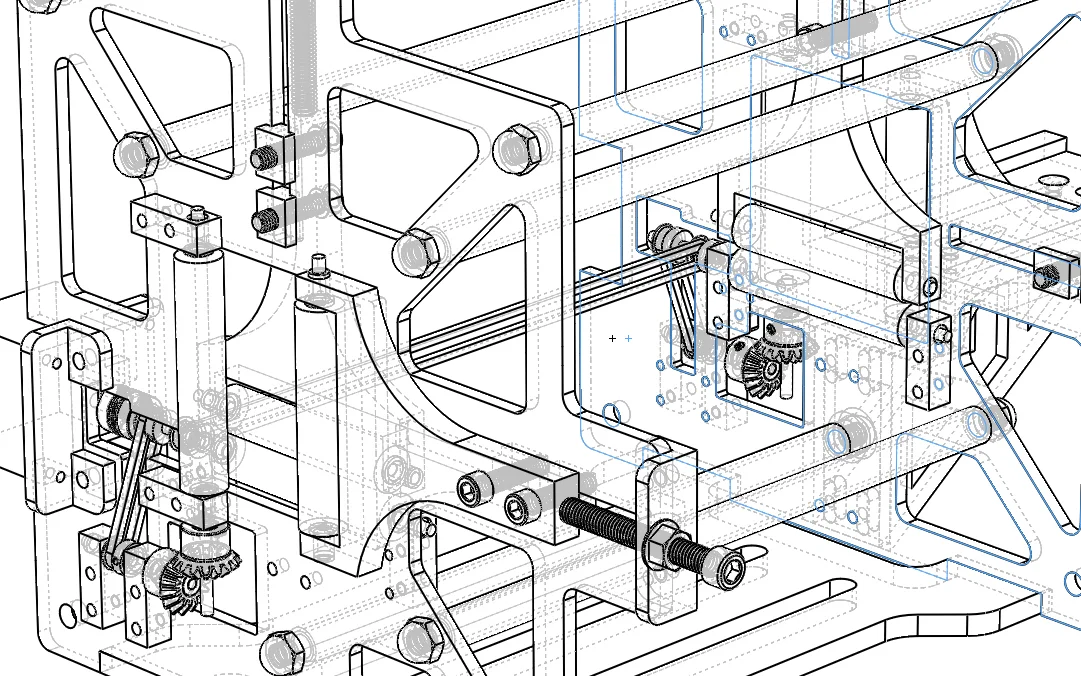

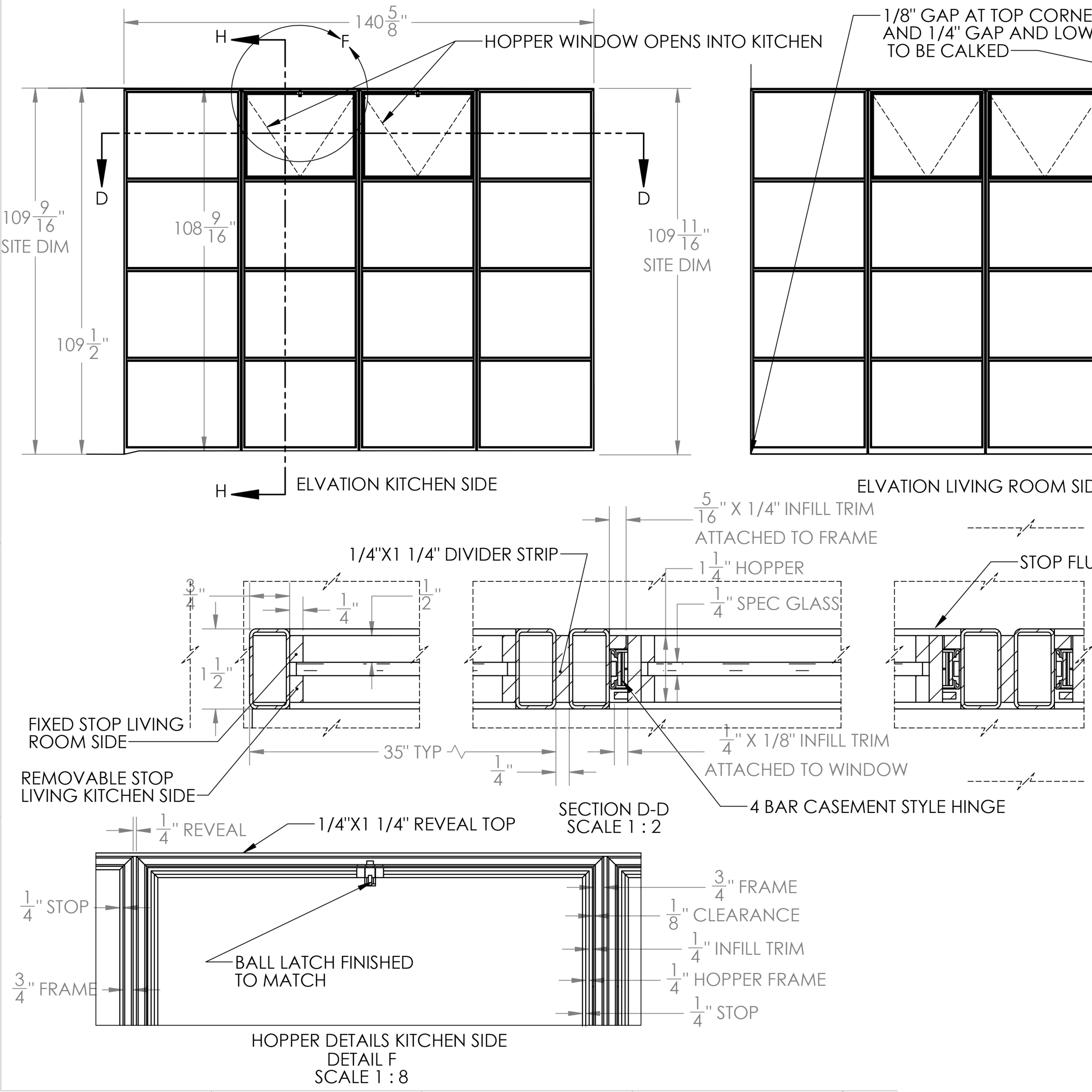

Freehand Metalworks offers full in house design engineering services including shop drawings, 3D modeling and analysis, cut file creating and editing for CNC plasma, water-jet, laser, etc. , CAM services for mill machining or lathe turning as well as complete production ready presentation packages.

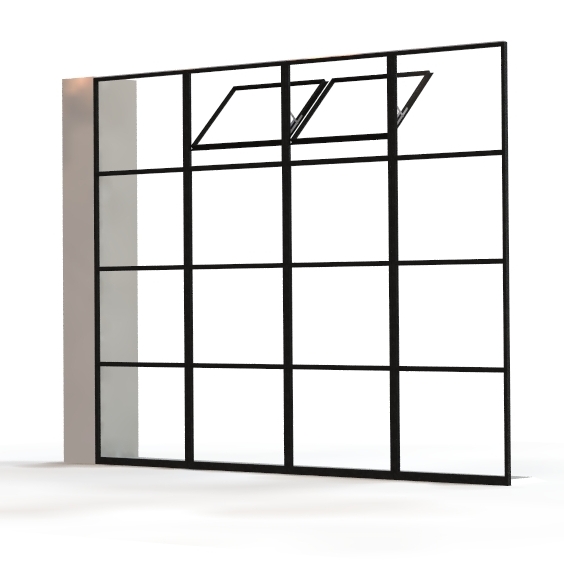

Your project can start at any stage, a classic napkin sketch, an inspiration image or just an idea. We springboard ideas into fully flushed out designs and create an exact working model of your concept. Freehand uses cutting edge software to analyze all aspects of a design and can answer any open question. We can determine weight and balance points, packaging and transport procedures, F.E.A stress analysis and flow dynamics. We produce shop drawings and a production packages ready for us and our vendors to build you a high quality product.

We collaborate with our clients to develop their design and come up with solutions to problems in order to make any project a reality. We evaluate requests and tailor design engineering and production methods for optimal performance and to fit within your budget. Freehand works to value engineer projects, to systematize production procedures and to produce a streamlined, elevated and high quality result. We pride ourselves in presenting a proposal that meets design intent and positions the project to be built to exceed expectation.